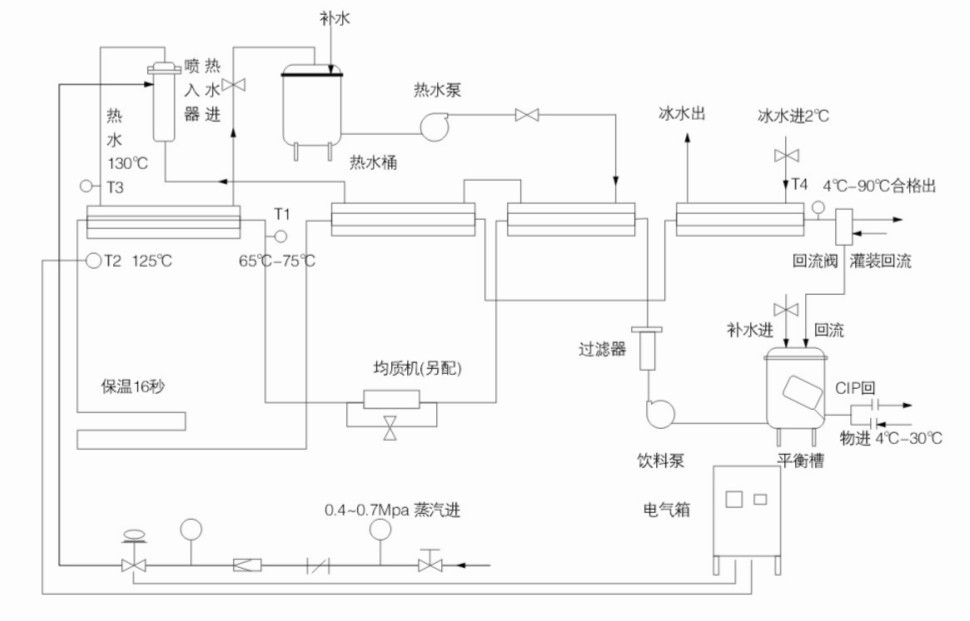

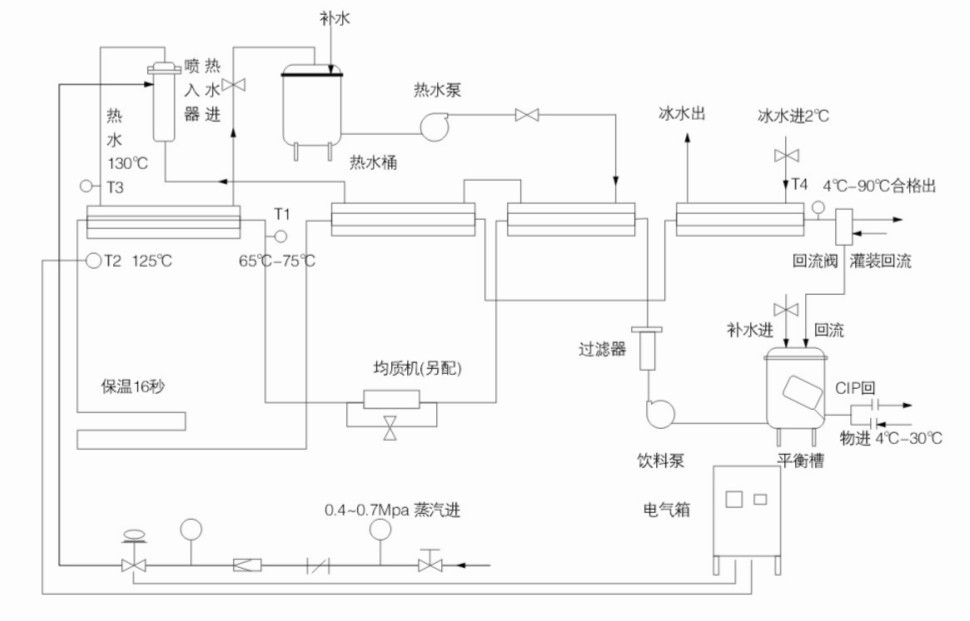

Scope of application The tubular sterilizer can be used to heat treat various dairy products, fruit juices, beverages, syrups, soy sauce, wine, vinegar, and liquid medicine. Compared with other types of sterilizers, it has the following advantages: 1. High thermal efficiency and materials After heating, 90% of the heat energy can be recovered.

2. The temperature difference between the heating medium and the material is small, which can realize gentle heating. The heat exchange tube adopts a bellows, and the material and heat exchange medium work in a turbulent state. The heat exchange efficiency is high, the scale is less, and the continuous working time of the sterilizer is increased. .

3. High degree of automation. The entire process from equipment CIP cleaning, equipment pipe sterilization to material sterilization can be automatically controlled and recorded.

4. Sterilization temperature control is accurate and reliable: the system that affects the sterilization temperature and the steam pressure, flow, and material flow are strictly controlled automatically.

5. The inner wall of the material pipe is polished with advanced technology, the pipe welding adopts automatic welding, the pipe design realizes completely automatic cleaning, and the equipment is self-sterilizing in the whole process to ensure the sterility of the system.

6. The system has strong security, and the system accessories are all selected products with good performance and high reliability. The system design attaches great importance to the human body. The safety of equipment, steam, hot water, materials, etc. have pressure protection measures and alarm systems.

7. The system has high reliability. The main components such as material pumps, hot water pumps, various valves, electrical components and actuators of the control system are all world-famous brands. Tubular pasteurizer and special sterilization for yogurt can be designed according to user requirements. Our company’s tubular UHT sterilization unit is specially designed for aseptic packaging equipment. It is suitable for various types of aseptic packaging, such as aseptic paper packaging, aseptic plastic film packaging, aseptic PET bottle packaging, etc. Especially used in the production of liquid milk and beverages.